Dear Architect / Designer,

This Guide has been prepared with you in mind - an attempt to answer your most common questions that you have about natural stone. Because you are all very busy people, we have tried to make this Guide brief and as compact as possible.

This Guide does not pretend to answer all the questions you may have or resolve all the doubts, but it does aim to address a large number of the questions that you have been asking our industry people over the years.

Hopefully you will be encouraged to explore the fascinating world of Natural Stone, become as paasionate about natural stone as we are and use natural stone in implementing you ideas.

- World Natural Stone Association

Stone & Man

Stone is a noble material. Man has preserved it in his victories and his laws, his religion and his art.

Since the distant origins, man has used it to protect himself. He has made stone his partner, because it is solid and he can trust it.

He learnt to sculpt it: and thus begun a long and passionate history of Stone and Man.

It enriches in a thousand ways and surfaces with a new sense of touch.

And luckily it restores the small treasures that are guarded in it: plants, seashells, fossils...

Man, when he builds or transforms his abode, should count on it, he cannot forget it, because the homes have soul, something of us.

Stone does not have a higher price than other materials. It is a natural wealth of our world.

What does cost money is the ugly: that which offends us and makes us vile.

The beautiful things, such as stone, give us a little more happiness every day.

The work of stone is our profession and we love it, passionately, and that is why, we with great pride, present it to you.

Like the living beings, the stone has multiple forms and variety of characters.

There are noble and solemn ones, lively and evocative. Radiant and bright as the firmament. Dark and mysterious as the depths of the lake.

Among the new materials stone has remained close to Man, in a privileged place.

The stone, like the skin, has its grain and its touch.

Its warm colour such as the blood, fresh as water. It absorbs light or reflects it like a mirror.

Stone provides an agreeable atmosphere, it is harmonious with the new and allows a lively contact with the things that surround us.

SECTION 1: Using Natural Stone

1. Why should I use natural stone?

Stone is a natural product. It is respectful with the environment, it does not destroy it. It has proved its validity as a building product through its use over centuries, proving its resistance and durability. It is easy to use, clean and easy to obtain. Natural stone encapsulates beauty, history, culture, and in the mind of the people in all the cultures of the world, it is intrinsically associated with luxury, quality and permanence.

2. Can my client afford to buy natural stone?

Most probably yes, because there are natural stones which are very economical in price, and even the customer with a limited budget is often surprised to discover how affordable natural stone really is. For each project a natural stone can be found which meets your preferences and fits your budget. When comparing the life cycle versus price with other alternatives, natural stone is definitely affordable. However, there are also stones in the market which are really exclusive and premium and, like all luxury products, command a premium price.

3. How can I find the natural stone suitable for my project?

You should first ask yourself the following questions- in which climate will the natural stone be used, and for what application ? Is the climate of the place extreme, very cold, or very hot, is it moderate, or is it humid, or is it a combination of several climates ?Is the application for which you are looking for natural stone, an exterior or is it for interior ? Is it a wall cladding or is it a flooring ? Based on the answer to the above questions, you should now look for natural stone on the basis of physical and chemical properties and the local standards.

SECTION 2: Types of Natural Stone

4. What kind of natural stones are suitable for my climate?

The key is to know the natural stone application- will it be used outside or inside? Will it be used for an interior wall cladding, or will the application be for a high traffic flooring? Or will its application be a kitchen countertop or in the bathroom, or for use on steps, or window sills? The analysis of the physical and chemical properties of the natural stone will guide you to the best choice.

5. What is the range of natural stones that exist in colours?

Endless! From pure white to the darkest black, and with a dazzling spectrum in between. The widest range of colors and their different combinations that exist in nature.

6. What is the geographical origin of the natural stones?

In just about all countries of the world natural stone is extracted in some way, after this unique, wonderful natural product is a result of geological formation, the process of which began in the initial stage of the formation of our planet, hundreds of millions of years ago.

7. What is the difference between granite, marble, limestone, sandstone, slate?

The difference between different types of natural stone starts right from the origin of its creation.

Granite is an igneous solid rock formed by magma with at least 20% quartz in volume.

Marble is a non-foliated metamorphic rock composed of recrystallized carbonate minerals, mostly common calcite or dolomite. Marble, in other words, is a metamorphosed limestone. Limestone is a non-foliated metamorphic rock composed of recrystallized carbonate minerals, commonly being calcite or dolomite.

Sandstone is a sedimentary rock composed mostly of sand sized minerals or rock grains.

Slate is a fine grained foliated homogeneous metamorphic rock, derived from the original shale-type sedimentary rock, composed of clay or volcanic ash, by means of low grade regional metamorphism.

Each of the different varieties have their own properties and appearance and determine their suitability for the different applications one may require.

8. Is there a catalogue that shows all the existing natural stones?

There are thousands of varieties of different types of stones, and new varieties are constantly appearing in the market as a result of extraction in new areas in different countries. The catalogues and the web pages of the different countries, or associations, individual companies, etc. show the stones that are extracted, or processed and marketed by them, and therefore, by definition, are only a partial database. It is also a good idea to check on whether the stone of your choice is still being extracted. Being a unique and irreplaceable product of nature, perhaps the deposits of the stone in question no longer exist !

9. Why can we not have all the different types of natural stones that are available shown in the catalogues? How can I ensure that I finally get the natural stone that I have chosen?

The catalogue is only the first step in the process of choosing a natural stone of your requirement. After analyzing the catalogues you should then ask for a real sample of the natural stone. In the case of selecting natural stone for a big size project, you could follow a further series of procedures. After having obtained a small sample, you could then ask your supplier to show you a small range of that particular natural stone variety initially so that you are, this way, better informed of what variations to expect. Obtaining the technical characteristics of the natural stone is then important. Bigger size samples could be asked for to get a better idea of how the final project will look like. If possible, in some cases, a visit to the quarries and factories may be useful and informative. Often a mockup at the source or the job site is done. And finally, quality control and inspection at job site may be needed. These procedures are often adjusted according to size of the project and country.

10. Is my stone sample an accurate/depiction of the stone?

Samples only serve as an indication of a stone´s physical characteristic. Being a natural product, absolute resemblance, naturally, cannot be guaranteed. There may be variation in colour and in patterns. Try to see a big size slab or many slabs of the stone, if possible- it will give you a much better idea of what to expect. The modern technologies make your job much simpler - the high quality images that can be seen on the tablets and smartphones can give you a very good idea of what to expect.

11. What are the different finishes that exist for natural stone?

There are a wide variety of finishes, all of them help to highlight the beauty of the natural stone and to serve a certain purpose of usage. Some of the finishes are- polished, honed, sawed, sawed finish with diamond disk ,bush hammered, flamed, aged, brushed, silk effect ( with or without shine), leather finish, antique, split finish, etc. Constant innovation by the industry has now allowed us to enjoy new finishes for different kinds of stones. The properties of each stone define which finishes can be applied and what changes take place to the aesthetic appearance of the material.

12. What are the different sizes recommended in natural stone?

Depends on the particular application of the stone. Mosaics are available in the market in sizes as small as 1cm x 1cm. And there are also stone tiles of 1.20 m x 1 m, and sometimes, even bigger. Widely used sizes, however, are 60 x 30 cm, 60 x 60 cm, 120 x 60 cm. The architect can define the size of the project. Recommended sizes by the manufacturers are based not only on aesthetic criteria but also take into account the size of the blocks extracted in the quarries and the optimization in the production systems in the factories to achieve minimum wastage.

SECTION 3: Technical Parameters

13. What are the general physical properties of natural stone that should be taken into consideration?

One should ask for the technical data sheet of the stone in consideration. The data will be of,

a) Water absorption

b) Compressive strength

c) Frost resistance

d) Resistance to Bending

e) Density

f) Abrasive resistance

g) Resistance of surface polish against weathering.

For external applications testing is becoming increasingly important especially in humid climates. In hot countries certain stones alter themselves, the physical appearance may change

14. What has the porosity to do with the water absorption of stone?

Porosity is related to water absorption and density of the stone. The higher the porosity, higher is the absorption of water phenomenon. Depending on the application, one should refer to the porosity scale.

15. What is the lifetime of natural stone?

Eternal. What is the lifetime of the Pyramids (and they exist for 4000 years now)? Or those cathedrals, temples, mosques, palaces and imposing official buildings the existence of which we are taught of when we are very young and still exist when we are at the end of our lives ? In some places thousand year old buildings have been destroyed and recycled stone used in new buildings. In our modern buildings, however, the natural stone life-cycle is usually considered around 80 years.

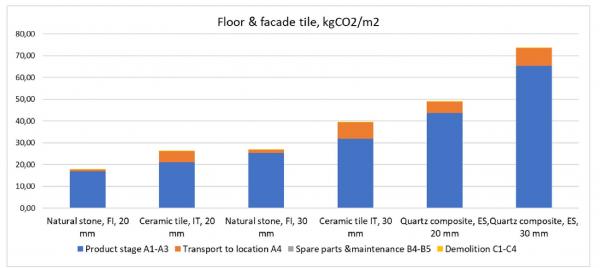

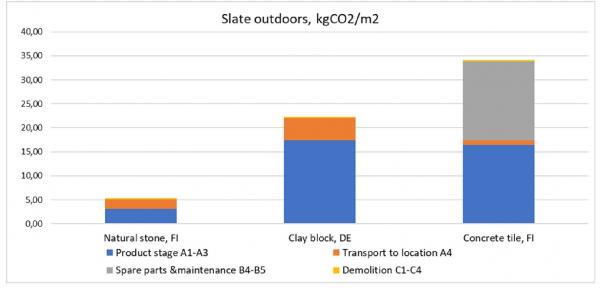

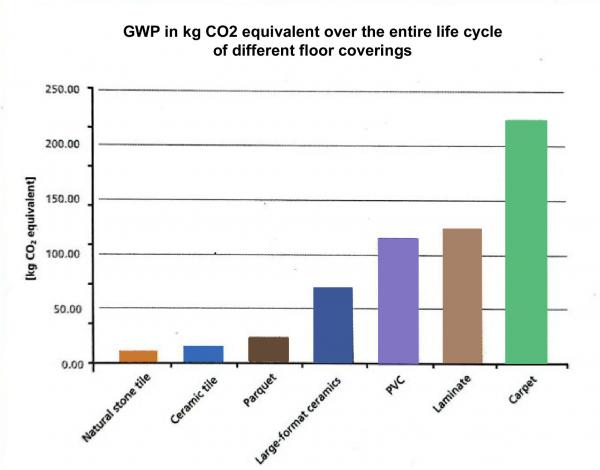

16. How does natural stone compare to other alternatives in terms of sustainability?

Sustainability in natural stone is best understood in the context of thinking of lifecycle. This would mean analyzing factors like preparation of raw materials, manufacture of pre-products, the production phase, end of life disposal, etc. Impact assessment includes energy consumption, raw material consumption, greenhouse effect, acidification, over fertilization, environmental toxins, waste, etc. Natural stone has already been made over hundreds of millions of years and it is mined and the processing is done by physical, and not chemical means. The sub-products can be recycled. The burden on the environment is low thus making natural stone the ideal hard floor covering, when green thinking and sustainability is the criteria. (For more information, refer to study done in Germany on hard floor coverings at www.wonasa.com).

SECTION 4: Installation of Natural Stones

17. What should be the structure of the building so that natural stone is used in external wall cladding?

The main condition is the structure of the building must be solid enough to carry the weight of the stone, and thus must be properly designed. The stone can be fixed to any structure using suitable assembling technology which is determined by the characteristics of the construction.

18. What is the appropriate thickness when using natural stone ?

The thickness is often subject to local standards which may vary from country to country. A key aspect to consider is the resistance of the stone to the force it is subjected to, in other words, it depends on the application. Generally speaking, in pavements, using granite, for example, if trucks are going to pass over it, use stone of more than 6 cm thickness, depending on the elasticity of the stone. 1 cm can be sufficient for the wall claddings. For kitchen countertops 2 cm stone can be used, though 3 cm and, in some countries, even 4 cm of thickness stone is also used for aesthetical reasons. Therefore, depending on the application and the properties, thickness may vary from 1 cm to 20 cm.

19. Is there any information available for fixing of natural stone in wall claddings?

There are many official and non-official organizations who have elaborated manuals which define the criteria and specifications in the case of wall cladding and flooring. The different manufacturers of anchoring systems should also be able to give you full and complete information on the existing technologies.

20. Can natural stone be installed on an existing floor/on a dry screed with adhesives?

The important thing is that no stress is caused which leads to deformation of the fixed stone and the whole structure remains durable. In other words, the surface on which the natural stone will be installed should be flat, solid, stable, and durable. There are many adhesives suitable for such floor assembling.

21. Can I install natural stone on my barbecue terrace?

Yes. Just make sure that the stone you use is a high density, low absorption one, this will mean the floor will stay clean for a long, long time.

22. Is the installation of natural stone tiles complicated?

Stone installation is best done and is easy when done by stone professionals. A great stone poorly installed may end up looking bad. If possible, ask your stone installer to show you his previous jobs on installation. The key thing to take into account is to choose the right stone for the right application.

SECTION 5: Maintenance & Treatment of Natural Stone

23. Is there any good method for polishing natural stone after installing the tiles to make the joints look even?

The joints can be filled with a polyester/epoxy based filler or adhesive. After hardening the entire surface is then grinded and polished. Expansion joints are then filled with a silicon sealant suitable for use in natural stone.

24. How can I avoid the situation of stains/efflorescence resulting from moisture and salts out after installation of the stones?

The stone should be treated on the back side and on the flanks of the stone with an alkali-resistant special coating in conjunction with silica sand.

25. What kind of maintenance is needed for stones already installed?

In general, natural stone is a construction material that needs very little maintenance if a little care is taken in treating it (depending on the stone). After installation a basic cleaning process is necessary to remove construction and installation related dirt. For daily cleaning water can be used in general; it is also recommended that from time to time special daily cleaning agents from reliable stone chemical manufacturers be used.

26. How can the natural properties of natural stone be improved by the use of chemicals?

If the problem is that the stone is breaking up, there are resins which help to consolidate stone. If the problem is that of oxidation, then the oxide needs to be removed first and then the surface protected with specific resins to make them impermeable. Where is the stone installed ? In case it is a wall perhaps a water-resistant liquid may be needed every 5 years. Or perhaps an anti-graffiti. In restoration work, stone can be improved, it can be protected against external agents. The chemicals help to enhance the natural beauty of the stone.

27. How can I protect/seal/impregnate my limestone to prevent staining?

Depending on the stone, it is advisable to use either non-colour changing or colour enhancing impregnators. Impregnators penetrate inside the stone surface, however, they do not form a coating layer. Impregnators allow the stone to keep its breathability but at the same time protect against the easy penetration of soiling substances (oil, water, dirt, etc.).

28. Is it true that polished natural stone is very difficult to keep clean compared to ceramic tiles ?

Not so, especially in the case of granite. In the case of certain marbles and limestone, it is important to follow the right guidelines for maintenance.

29. What are the technical standards for stone used in exteriors?

There are different standards in different places. In the USA, for example, the ASTM standards are followed, in most of Europe the EN standards are the norm. In the UK, the BSI standard prevails.

30. Is natural stone radioactive?

Radioactivity is all around us in the environment, it is part of nature, emitted by the sun, it is in the soil, air, etc. It is also emitted by the modern appliances like TVs, etc. Granite does emit very small amounts of radioactive gas radon, and also by direct radioactive decay. Therefore, the appropriate question to ask is -is the level dangerous? The answer is very clearly - NO. Several scientific studies have been conducted, mostly in USA, on this matter and they all ratify this conclusion. (For more information on the matter, consult www.marble-institute.com/consumers/granite_radoninfo.cfm)

31. What steps should be taken to avoid problems when fixing stone or when doing so in old buildings?

By properly following existing established standards and guidelines, you should have no problem. How will the stone be installed? There is an appropriate stone for each place and application.

32. The natural stone installed is losing polish. What should be done?

If the stone is bland, you can fill it with a liquid resin that strengthens it. If the stone has scratches on the floor but you do not want to polish the whole floor, then use products which even though they do not remove the scratch, end up giving the impression that the scratches are no longer there. Alternatively, in the case of a big floor, you may need to grind and polish it again.

33. There are holes in the stone installed. How do I solve this problem?

Holes can be filled with transparent and coloured fillers. Depending on the size of the holes and their number, either a spot repair with a UV-Filler or a treatment of the whole surface may sometimes be necessary.

Useful Tips for avoiding problems when using Natural Stones

- In very cold and rainy weather climates, for external use, avoid using polished or fine honed finishes in natural stone floorings in exteriors, since they will create problems of slippage. Better to use flamed, or bush hammered or any rugged finish. It is advisable to apply an anti-slippage finish to the stone.

- To avoid anti-slippage on stone installed inside a building, anti-slip stripes made of 2-components - Âepoxy containing corundum should be placed on the stairs. In the entrance areas, anti-slip agents enable roughening up of the polished surface.

- To avoid efflorescence / salt / moisture stains on stone installed, the stone should be protected on the back side and the flanks with an alkaline-resistant special coating in conjunction with silica sand.

- When doing exterior cladding made of a soft natural stone (like soft limestone, for example) in a cold climate, care should be taken to follow the right criteria.

- When deciding on the sizes of natural stone pieces for cladding or staircases, also consider whether there may be difficulty in transport, in handling and assembling of the pieces.

- When choosing natural stone for countertops, it is not enough to consider only the visual, aesthetic aspects, one should also consider the physical properties. Limestone and marbles should, in general, not be used as kitchen-tops, since they are not acid resistant. To protect against stains from oil and grease, a special impregnator should be used.

- For countertops use smooth finishes avoiding the rough finishes which are more difficult to clean.

- Fountains are often made of concrete and then finished with stone elements. Often the joints look ugly after a short period of time due to water penetration effect. This problem can be avoided by using solid and well sized elements eliminating the joints to the minimum number. Alternatively, it is advisable to bond the stone cladding on a fountain with 2-component- epoxy- adhesives and also fill the joint with 2- component-epoxy- adhesives. In this case, no efflorescence from the cement will appear.

- When using under the floor heating, some stones (like travertine, for example), which are filled, the filler can pop up due to the heat. This is not a defect. Particularly if the heating is done with water, run it before installing the stone tile so that the concrete settles down, this way the risk of the stone cracking is highly reduced.

- Some stones need to be resined on the face, or reinforced on the back side. This way these stones become more stable, and we can now enjoy a wider variety of what is available in nature of natural stones.

Prologue

Natural stone is beautiful, representative, and thanks to modern techniques of quarrying, manufacturing, and processing, affordable for almost anyone. Each slab is a piece of nature and, therefore, unique.

Natural stone remains, ‘naturally,’ unchanged over centuries; it is not subject to the constant fluctuations of market currents, to what is ‘hip’ and ‘fashionable,’ as is the case with artificial/synthetic materials. Furthermore, natural stone provides the designer with many a possibility of usage and application. Flooring and paneling can be treated with a number of surface applications: depending on the surface treatment, the stone appears lighter or darker, its colors can be more or less intense, it can feel smoother or rougher. Natural stone can be manufactured in massively diverse ways. As such, flooring and paneling, processed, to offer just one example, with ceramic tiles, can be complemented with as many other items as massive shower trays, washbasin, shells and panels, basin and pool bordures, monolithic bathtubs, and even sculptures.

There is a plethora of different stones with a wide variety of colors and textures, each one with its own properties and characteristics. This individual variety comes with its own structural-physical properties.

Now, this rich variety can be both a blessing and a curse. It can be the reason for wrong choices and improper treatment regarding cleaning, protection, and care. These mistakes in treatment cause problems which can often, unfortunately and unjustifiably, bring natural stones into discredit. Even misnomers, such as referring to all hard stones as “granite,” have led to an unjust discrediting. Not all hard stones are “granites,” and very often what is referred to as “granite” is not a genuine granite in the stricter sense.

This guide provides the consumer with an “easy-to-read” manual in the form of questions and answers and helps him or her to master the daily challenges of preserving the original quality of natural stones in order to enjoy for the longest possible time this precious and valuable material.

Section-1. TYPES OF NATURAL STONE

Q1. What is the difference between granite, marble, limestone, sandstone, slate ?

The difference between miscellaneous types of natural stone starts right with the origin of its creation:

Granite is an igneous rock with at least 20% quartz and up to 65% alkali feldspar by volume. Marble is a non-foliated metamorphic rock composed of recrystallized carbonate minerals, mostly common calcite or dolomite. Marble, in other words, is a metamorphosed limestone. Limestone is a non-foliated metamorphic rock (sedimentary rock) composed, mainly of skeletal fragments of marine organisms such as coral, forams and mollusks. Its major materials are the minerals calcite and aragonite, which are different crystal forms of calcium carbonate (CaCO3). Sandstone is a sedimentary rock composed mostly of sand sized minerals or rock grains. Slate is a finely grained, foliated homogeneous metamorphic rock, derived from the original shale-type sedimentary rock, composed of clay or volcanic ash, by means of low grade regional metamorphism.

Each of these different varieties has their own properties and appearance, and requires therefore an individual approach and differing applications.

Q2. What is hard and soft stone?

Generally, stones are categorized into hard and soft stones.

“Hard stones” include granite, gabbro, syenite, and diabase. The materials subsumed under this category are wear-resistant and in most cases suitable for all forms of installation. Commercially, these stones are mistakenly referred to as “granite.” Equally classified as “hard stones” are porous vulcanite and slate stones. These, too, are suitable for any kind of installation.

“Soft stones” range from so-called sedimentary rock such as limestone and argillaceous shale to metamorphic rocks such as marble. In most cases suitable for flooring, these stones are mostly used for paneling and less demanded areas. Commercially, these stones are commonly referred to as “marble” or “limestone.” Sandstones, too, offer a variety of possible applications if used as soft stones, preferably as flooring material.

Q3. What is the stability of the natural stones against acidic chemicals?

Is the natural stone acid-sensitive (limestone, marble, many sand stones, argillaceous stone), then those chemicals are not to be used:

Generally, soft stone (such as limestone, marble, many sand stones, argillaceous stone) are acid-sensitive and are therefore not to be treated with acidic chemicals. Hard stones (such as granite), on the other hand, are acid-proof. However, the general classification of “granite” includes some gabbro and basalts which are not acid-proof, such as, the Indian Star Galaxy or the South-African Nero Absoluto and Impala, as well as different kinds of diorites such as the Brazilian stone Tijuca. These “relatives” of granite consist of a wholly different chemical composition and can therefore not be classified as granites. Additionally, what is commonly referred to as “black granites” include natural stones which are not granites at all and which, therefore, are also not acid-proof.

Q4. How to choose the right natural stone for a project?

Besides the appearance, colors and design of the natural stone the most important criteria for choosing the appropriate climate for indoor and outdoor applications are: frost resistance, abrasiveness, water absorption, acid resistance, suitability for flooring and cladding, polishing possibility.

Section-2. PRE-INSTALLATION CARE OF NATURAL STONE

(In the factory or outside factory stage)

Q5. Why is it necessary to pre-protect the stones before application?

The main concern before application is begun is how to protect the stone against attacks. Protection concerns all six sides (surfaces) of the stone.

Q6. How to pre-protect the Natural Stone for indoor application?

Flooring and Walls (Façade dry-cladding): The best way to prevent blooming and stains caused by moisture and to avoid or reduce rust stains is to impregnate all six sides (surfaces) with a suitable solvent- or water-based Stone Protector.

Walls (Façade wet-cladding): In case of wet-cladding it is recommended to seal the back-side of the natural stone with a thin coating layer of a 2-component resin system with quartz sand dispersed on it. The quartz sand layer acts as an adhesion primer to the laying cement mortar. Treat the remaining 5 sides with a suitable solvent- or water-based Stone Protector.

Q7. How to pre-protect the Natural Stone for out-door application?

Flooring and Walls (Façade wet-cladding): In both cases it is recommended to seal the back-side of the natural stone with a thin coating layer of a 2-component resin system with quartz sand dispersed on it. The quartz sand layer acts as an adhesion primer to the laying cement mortar. Treat the remaining 5 sides with a suitable solvent- or water-based Stone Protector.

Q8. How to pre-protect the Natural Stones (marble as well as granite) by laying a floor or to install by wet-cladding, if the back-side is already treated (protected) with net and resin, which could not adhere, using a cement mortar?

In both cases it is recommended to treat the back-side of the natural stone with a thin coating layer of a 2-component resin system with quartz sand dispersed on it. The quartz sand layer acts as an adhesion primer to the laying cement mortar. The other 5 sides we treat with a suitable solvent- or water-based Stone Protector.

Walls (Façade dry-cladding): The best way to prevent stains caused by moisture is to impregnate all the six sides with a suitable solvent- or water-based Stone Protector.

Section-3. POST INSTALLATION STONE CARE

After the end of installation two important procedures follow: the initial post-installation cleaning and the basic protection.

3.1. Initial Post-Installation Cleaning

Q9. With what forms of staining and dirt are we dealing with?

1. Cleaning blown-up coarse dirt (e.g. sand) and fine dirt (e.g. coarse dust).

2. Cleaning adhering dirt, either water-soluble (e.g. soil or fine dust) or not water-soluble (e.g. residues of mortar, cement, or joint fillings, putty, adhesive labels, marker-lines)

3. Cleaning special stains (e.g. residues of epoxy resin or stains caused by packaging material that had been placed onto the surface).

Q10. How can coarse dirt be removed?

Coarse dirt can only be removed mechanically by using an upright vacuum cleaner or vacuum sweeper. Do not use a broom, since that would blow up quartziferrous dusts which are highly damaging to one’s health. Avoiding any production or proliferation of dust is paramount.

Q11. How can I remove the adhering dirt (water-solvent)?

Water-solvent dirt is removed by damp- or wet-wiping. With vacuum scrubbing a mechanical support is being provided (scrubbing) that helps unstick and detach of adhering dirt while suctioning the dirty water. Same goes for wet scrubbing with brush or pad and subsequent wet suctioning.

Q12. How can I remove the adhering dirt and stains (not water-soluble)?

Dirt and stains that cannot be removed with water are differentiated based on their solubility:

- Dirt and stains that can be removed with acidic cleaning products, e.g. cement residue, mortar residue

- Dirt and stains that can be removed with alkaline cleaning products, e.g. waxes, fats, general soiling’s.

- Dirt and stains that can be removed with solvent cleaning products, e.g. oils, adhesive tapes.

Q13. How can cement residues be removed without damaging the stone surface?

Considerable maltreatments can happen with the cement residue removal. Cement residue are rests of cement join fillings sticking to the floor surface. These can only be removed by using acidic solvents. Cement residue removers are, consequently, acidic products, which dissolve residues of cement and lime. The composition of the products (kind and concentration of the acid) can vary considerably. Every kind of acid has its pitfalls and not all of them are universally applicable to all natural work stones. Depending on surface treatment and intensity of pollution, mechanical assistance should be added to every application of cement residue remover.

If the stone is not acid-resistant, a mechanical removal with an alkaline solvent can be attempted; however, the cleaning product will not immediately and entirely remove dirt from the surface.

In the acid-sensitive natural stone with a rough surface, removing cement residues presents a different situation. Often one is faced with the question of whether to grind over or rework the natural stone to the entire floor material. In this case, it is possible to use a highly-diluted cement residue remover after having pre-wetted the surface in order to acidify the surface, if the resulting roughening of the stone remains unperceivable on its rough surface and the damage remains within acceptable terms.

Q14. Why do I have to pre-wet the acid-sensitive natural stone before applying acidic chemicals?

The easiest way to protect both the natural stone and the joints from acid is to pre-wet the floor. The rule is simple: if water has got in, then acid cannot get in. The cement residues then lie on the surface and can be dissolved by the acidic influence. Most cement residue removers dissolve the cement, but do not clean the its surface. For the sake of neutralization, the flooring must be cleaned with an alkaline basic cleaner. It is advisable to always test the product on an inconspicuous area, since it is never completely clear what the exact reaction is going to be between stone and product.

Q15. What happens with the joints during the cleaning process?

The joints are very acid-sensitive, even those made of synthetic material. As a general rule, there should be a ten-days waiting period between the jointing and the cement residue removal. Additionally, pay attention to the guidelines of the grout manufacturer.

3.2. Post-Installation Protection (Basic Protection)

Q17. Is a final protection necessary?

Yes. The pre-protected surface of natural stone after the intensive cleaning with more-or-less strong chemicals and in addition to the mechanical strain during the cleaning is not enough for a long-lasting protection. In case the natural stone after laying will be reground and re-polished (mainly for soft stones),a basic protection is compulsory.

Q18. How many kinds of protection do we have at our disposal?

For the care and protection of natural work stones two basic groups of processes and products are available:

- Impregnation (not layer-forming products) and

- Sealing (layer-forming products)

Impregnations are classified as water-repellent (hydrophobic) and water- and oil-repellent (hydro- and oleophobic). The applied impregnation product penetrates into the surface pores of the stone and is taken up by the poricidal walls. A capillary transmission of fluids into the stone is made impossible. Impregnation products do not entirely close up the pores of the natural stone, however, transmission of water is only possible in the form of vapor, no longer in liquid form (water vapor diffusion). Depending on the product, the rate of water vapor diffusion may equally decline.

Q19. What is the difference between sealing and impregnation?

Unfortunately, in the English language, we use for both kinds of protection, the word “sealer”, “sealing”. The word “sealing” in case of impregnation is misleading. It implies that the stone is so entirely covered that it is unable to breathe, which is not the basic property of the impregnation.

Sealing can be achieved; however, it depends on the kind of stone. For example, we could do sealing on “sheet stone” like slate, or where the back-side of natural stone is open to ventilation (e.g. ventilated façade).

Impregnations are not layer-forming, but penetrate into the stone structure and cause a visible reaction on the poricidal surface. They emulate the natural vapor diffusion rate of the stone. Therefore, they do not provide a complete protection against stains, they solely prevent stain-producing substances from entering too easily into the stone. Impregnations do not provide protection against acids, such as those found in fruit juices.

Sealings, on the other hand, are layer-forming products. They should not be applied to backstage moistened coverings since they prevent a diffusion of humidity and can therefore cause discolorations and whitening underneath the covering. Sealings should not be used on or around kitchen countertops, since they are not particularly heat-resistant or scratch-proof. To avoid unnecessary trouble or reclamations, the costumer or client should be thoroughly briefed beforehand.

Q20. Who should perform the impregnation?

In general, a stone expert, e.g. a stonemason, who is familiar with the impregnation of flooring and other surfaces made of natural stone. The person should, however, prove conversant with the application of adequate products as well.

Q21. Can impregnation protect the stone from acidic influences?

Impregnations provide primary protection, i.e. the absorption of stain-forming substances is being delayed and reduced by impregnation. Impregnation does not protect against acidic influences. It is important to remember that drinks such as fruit juices, sparkling water, fizzy drinks etc. are considerably acidic and can attack acid-sensitive stones. Stains caused by acidic influence are therefore immediately to be removed.

Q22. How many different types of impregnation products are there?

Depending on the respective solvent and effects, impregnations are categorized into:

- water-repellent (hydrophobic), water-based, without color-enhancing

- water-repellent (hydrophobic), solvent-based, with and without color-enhancing

- water- and oil-repellent (hydrophobic and oleophobic), water-based without color-enhancing

- water- and oil-repellent (hydrophobic and oleophobic), solvent-based with and without color-enhancing

It is important to note that even with impregnation products which are not color-enhancing, a deepening of color, albeit a slight one, can occur the color depending on the stone. Therefore, a test-application on a sample area should be conducted before the actual procedure. If need be, obtain previously an official approval from the client. In certain cases, a more or less intensive deepening of color might be in the client’s interest.

Solvent-based impregnations give the impression of a more intense color. Thanks to their superior penetrating properties, these products achieve a better effect on stones with diminished absorption.

Q23. What does one have to take care of before beginning with the impregnation?

A dry and cleaned stone surface is especially important for a successful impregnation. Before any impregnation, the surface must be dried and cleaned. All stains must have been removed and the surface should be absorbing. A thorough cleaning is the essential pre-condition for a later successful protective treatment. Stains that have not been properly removed before treatment are a lot more noticeable and much harder to remove post-impregnation.

Q24. How can one decide on a water-based or solvent-based product?

Dry stones have higher absorption capabilities and are therefore better suited for solvent-based impregnation, which provide a superior protection compared to water-based impregnations. However, solvent-based impregnation cannot penetrate a wet stone and then sink into its capillary structure. Should the stone be considerably moist or not properly dried, the following problems can occur during a solvent-based impregnation:

1. Film formation on the stone surface

2. Proper drying is hindered due to temporary clogging of the capillary (possible spotting due to internally harboured salts)

3. Adverse reaction of the agent with the prevailing moisture (permanent discoloration)

4. Insufficient protection effect can cause marginal damages.

Water-based impregnation is suitable for natural stones which are difficult to dry well. Water-based impregnation has decreased penetration properties on less-absorbing stones. It therefore achieves a less than ideal protective effect, but also does have less “damage potential.” If applied, the following problems can occur:

1. Insufficient protective effect

2. Film formation on the stone surface

Q25. What causes problems during and after impregnation?

When it comes to impregnation, the following conditions can cause problems:

1. Too much remaining moisture after laying and cleaning, respectively.

2. Overapplication: surplus on the stone surface (film formation).

3. Underapplication: too sparingly applied product leads to insufficient protection.

4. Stone warming (sunlight exposure, underfloor heating) causes film formation due to the solvent evaporating too rapidly.

5. Insufficient pre-cleaning (rests of cement residue, other forms of pollution and residue of previously applied care products).

6. Exposure to humidity immediately following impregnation (especially in outdoor areas, e.g. rain).

Q26. What is the behavior of “dark stones” to impregnation?

Several dark stones can alter their color after an impregnation treatment. In many cases, this is a desired effect. There are many natural stones, however, which react differently to impregnation solutions and end up covered in stains and spots. This often happens in rough materials such as quartzites and gneiss. Other stones, such as the Norwegian Otta Phyllit, can lose their so-called 3D-effect, a three-dimensionally looking shimmering on the surface, after an impregnating treatment. The impregnation of such sensitive kinds of natural stone specially require an impregnation with Nano-effect. These products are applied onto the clean and dry surface. After an application time of 5-10 min. the residues are being removed. The full impregnating effect sets in just after 2 hours. The product does not cause any color deepening.

Q27. How can I determine the dryness of the stone surface?

There is a simple test to determine whether the stone surface is sufficiently dry. Lay a foil or newspaper over the surface. A “sweaty” foil or a “wrinkly” newspaper point towards a prevalent humidity. This test might be imprecise, but can be easily executed.

It is important to stick to the necessary waiting time between cleaning and application. Often, a floor surfacing seems to be completely dry within an hour after cleaning. This appearance may be deceiving. Far from being dry, the stone may be completely soaked inside its capillaries. The duration of the drying time depends, among other things, on the absorbing capacities of the stone and climatic conditions such as temperature and humidity as well as existing ventilation.

Q28. Which tools are used to apply stone impregnation?

To impregnate a stone, the product should be applied fully and evenly with a paintbrush, seal brush, flat dust mop, and short paint roller in a cross stitch pattern. Impregnations can be sprayed too, e.g. on vertical areas. Liquid impregnations are best sprayed onto the surface, since this technique facilitates a more even application than using a roller. During application, it is important to avoid leaving behind puddles. Surplus material must be removed with cloth or paper before drying up.

Q29. Is possible to repeat the impregnation?

Re-impregnations are unproblematic with liquid products, but can cause problems with solvent-based products. It is therefore advisable to apply sufficient impregnations and to facilitate an immediate and complete absorption, since a surplus of impregnation will cause a film formation on the surface which will then have to be removed. A film on a stone surface impregnated with solvent-based products will cause uneven abrasion under mechanical exposure (e.g. footprints). Such films can easily be removed up to one week after impregnation with a basic cleaner or an impregnation remover. Nowadays, many natural stones with polished surfaces have been pre-treated as early as in the factory (resination) stage. As a result, the stone’s absorption properties are highly diminished. Surfaces of these stones can change considerably when treated with solvent-based products.

Q30. What is the Life-time of impregnations?

Regarding liquid and solvent-containing impregnations, the life-time of the treatment depends strongly on cleaning and care of the impregnated areas. If cleaned with alkaline substances, water- and oil-repellant impregnations are much durable than impregnations that are only water-repellant. Kitchen countertops should be re-impregnated once a year, surface coatings in bathrooms or swimming areas once every three years (showers and washstands once a year). For coatings in regularly utilized areas which are carefully maintained re-impregnation should be considered every 5 to 10 years.

3.3. Maintenance of Natural Stone

Q31. Which are the well-established cleaning methods?

Sweeping:

The old-fashioned broom is still a valuable part of everyday maintenance of any floor surface – natural stone included. It is very important to remove soils from flooring surfaces. Soils are abrasive. The more often soils are removed, the longer the floor will retain the original appearance. Use a broom with a bristle that matches your surface. A soft broom or brush is recommended for smooth surfaces like marble, sandstone and limestone. A medium to soft bristle is ideal for textured surface.

Vacuum:

A good vacuum cleaner works better and more efficiently on textured surface than a broom. Use a vacuum on any horizontal surface when large areas are involved, since it is, in most cases, faster than sweeping.

Damp Moping:

A damp mop is capable of picking up microscopic abrasive soils and potential staining agents. Damp mopping is recommended for most smooth surfaces on a regular basis. Best done after sweeping or vacuuming.

Cleaning:

It is essential to clean a floor regularly. The working conditions will dictate its frequency. The most widespread problems encountered with stone floors are related to the floor simply not being regularly cleaned.

Rinsing:

Rinsing is one of the most critical steps in regular floor maintenance. Dirty mop water residue is common and a cause for much complaint. A two bucket rinse method is highly effective in keeping floors from graying out due to soil residues.

Abrasive (mechanical cleaning):

Abrasives are sometimes useful as a cleaning agent but should be limited to non – polished surfaces. Abrasives may be combined with detergents or soaps for scouring a surface and removing thin layers from the surface. There are many different types of materials used as abrasives – soft abrasives may be composed of nutshells or feldspars, hard abrasives can be silica quartz, carbide or even diamond.

Q32. What can ruin or cause damage to a stone?

Acid:

Spills from drinking liquids or food containing acid will etch (dull mark) marble and limestone surface. Also the wrong declaration of some group of natural stones can cause irreparable damages. The so called “black granites” which are partially basalt such as Tiger Black or Chinese G684 or Gabbro as Star Galaxy, Nero Absolute, Impala or in the case of Belgian granite, which is limestone, all of them are sensitive against acid. In such cases, lemon juice, orange juice, carbonated beverages, cranberry juice, apple juice, wine, tomato, etc. may cause a dull mark that may be of a coin size or spread over the surface.

Alkaline:

In addition to chemicals containing acid, chemicals that contain high alkaline or bleach can damage floors to lose its shine and elegance.

Moisture:

Local water may contain chlorine, salts, magnesium, potassium and other minerals. When water is used continuously to clean the marble and limestone floor it may ruin certain type of marble or limestone by causing pitting, spalling and yellowing. This is why it is important to protect the floor with a sealer (impregnator).

Scratches:

Sand and grit carried from outside by shoes can easily scratch and abrade the marble surface like a sandpaper. Unprotected furniture legs may leave scratches too. Dragging heavy objects or sharp items on the floor can cause very deep scratches or gouges that may be permanent.

Stains:

Even a hard, natural stone such as granite is still porous and can easily be discolored by spills from food, sitting pots, metal furniture legs, oil, ink, water damage, etc.

Improper Maintenance procedure:

Continuous use of water as the sole cleaning agent (without chemicals), or using dirty mops, or not changing the cleaning solution frequently enough, can cause soft and hard stone to look dingy, streaky and unattractive.

Improper Maintenance program:

Not having a steady use of dust mop and damp mop cause a decrease of the gloss. In addition, a yearly maintenance may be required to revive the gloss especially when the floor is exposed to medium or heavy traffic.

Q33. What are the recommendations for a successful initial (basic) cleaning?

◼ For Floor / Stairs (indoor)

1. Soft stone such as marble, limestone (not stable against acidic cleaner).

For contaminates such as basic dirt, dirt layers, thin layers of wax, superficial oil and grease stains, soot, rubber and tar stains, even efflorescence and cement rest -

Clean with a light alkali cleaner (pH=10). Don’t start with the concentrate form. Depending on the dirtiness, start with a water dilution 1:5 to 1:25.

2. Hard stone such as granite, gneiss (stable against acidic cleaners).

Clean with alkali cleaner as well as with acidic cleaner (pH=1). Because many of the hard stones such as the so-called “black granite” (Tiger Black, G684) are not stable, it is necessary to conduct a pre-treatment test with the acidic cleaner on an inconspicuous area. Do not use immediately in concentrated form and pre-wet the surface. Acidic cleaner based on hydrochloric acid react with many hard stones to cause rust. Other hard stones as Labrador lose their gloss immediately. Acidic cleaner based on acetic acid attacks the fittings.

◼ For Façade, Wall terrace (outdoor)

1. Soft stone such as marble, limestone (not stable against acidic cleaner).

Clean with a light alkali cleaner (pH=10), algae & mildew remover, which is a slightly alkali cleaner (pH=11) based on active chlorine compounds. Use undiluted. Do not allow contact with plants, metal, wood and cloths.

2. Hard stone such as granite, gneiss (stable against acidic cleaners).

It is possible to clean with alkali cleaner as well as with acidic cleaner or/and algae & mildew remover.

◼ Kitchen-countertop, Wash basin, Sanitary items

1. Soft stone such as marble, limestone (not stable against acidic cleaner).

Clean with an alkali cleaner (pH=10)

2. Hard stone as granite, gneiss (stable against acidic cleaners.

Clean with a strong alkali cleaner (pH=12)

Q34. What are the recommendations for a successful daily cleaning?

It is usually not necessary to clean daily unless it is a high traffic area like hotel lobby, etc. For all floors the daily cleaning should be carried out by a cleaning product with pH = 7 neutral and water-based.

Clean with a neutral cleaner (pH=7) or stone soap. Surfaces are to be slightly moisted with a wiper to remove the dirt. Dilute the concentrated cleaner in water 1:50 to 1:100 and clean the surface with a slightly moistened cloth. Let the surface dry for 10 minutes. The products can also be used in a brush cleaning machine with a sucking device.

It is important to prevent the product from creating layers or stripes on the floor to support the protective effect of the impregnation. The water solution of the cleaning product should be applied with a mop. Dirty solutions should be mopped up regularly. Remove loose debris by sweeping or vacuuming before applying the cleaning solution.

Q35. Which are the recommendations for a successful periodical cleaning?

◼ Periodical initial (basic) cleaning

Due to heavy traffic or other circumstances it can be necessary to carry out periodically an initial cleaning with a slightly alkaline cleaner. The application period depends on the grade of pollution; it can be carried out every 3-12 month.

The product has to be diluted with water approximately 1:20 up to 1:50 depending, on the degree of pollution.

The product must not affect the impregnation of the stone.

The cleaning solution should be applied with a mop. Dirty solution should be mopped up regularly.

◼ Spot and stain cleaning

Although impregnation is used, it can be at times necessary to remove spots of heavy pollution and stains. If required, preferred products are:

Rust remover for granite or for marble, Oil- and Grease Remover, Algae- and Mildew Remover etc. Also, bleaches are typically oxidizing agents (they generate oxygen) and are useful in stain removal. Enzyme types are available which are non – hazardous.

Q36. How to protect natural stones used for highly strained surfaces as such as kitchentop, table top, bar counter etc.?

Protection:

The surface of the natural stone has to be clean, stain free, dry and with enough absorption properties. Nowadays most of the natural stones are already treated in the factory. As a result, the stones show altered absorption properties. Therefore it is recommended to use an oil- and water-repellent, solvent-based impregnation. In any case is recommended to prepare a sample area in order to examine the efficiency of the impregnation.

Due to the permanent contact of impregnation with foods, is essential that the protection is approved as being of food-safe quality.

Q37. How to clean and care natural stones used for highly strained surfaces as kitchen tops, table tops, bar counter etc.?

Cleaning and care:

If cleaned immediately, many food stains can be taken care of with a simple damp cloth. Once dried up or involving fat, stains and soiling can no longer be cleaned so easily. For such residues, mild cleaning products with oil- and fat-solvent qualities should be used. Products that are extremely alkaline or highly degreasing can, over the long-term, damage the stone’s impregnation. Many manufacturers offer spray cleaners that are easily applied. They have a cleaning and protecting component and therefore provide a removal of stains and protection of the stone in one single working step. If used regularly, the spray cleaners can prolong the interval time between subsequent impregnations.

At the first sight of dark stains caused by oil- and fat-containing food, an immediate reaction is essential. Among the most effective solutions are oil removal pastes. These cleaning products guarantee a long application time, an essential factor if pollutions need to be dissolved that are deep-seated within capillary structures of the stone. After the removal of stains the protective impregnation needs to be renewed.

Section-4. REMOVING STAINS

Q38. How to remove stains from the surface of natural stone?

1. Soft stone such as marble, limestone (not stable against acidic cleaner).

If there are contaminates such as; basic dirt, dirt layers, thin layers of wax, superficial oil and grease stains, soot, rubber and tar stains, or even efflorescence and cement residue -

Remove with a light alkaline cleaner (pH=10).

What to do if there are superficial rust stains produced by ferrous substances or objects, such as fertilizers, tools, iron pasts etc. -

Remove with a slightly alkali rust remover (pH=9)

2.Hard stone such as granite, gneiss (stable against acidic cleaners).

If there is rust and inorganic discoloration: to remove inorganic discolorations, such as rust stains, use Rust remover, a product based on phosphoric acid. It is important to make a test patch in an inconspicuous area to ensure that the surface is acid resistant.

If there are lime residues, rust marks and heavy soap residues: They can be removed with an organic acid based disinfectant cleaner with (pH=1)

Mortar, lime residue, efflorescence, cements films and other stubborn deposits on tiles or slabs:

They can be removed with an acid-based concrete film remover, which is free of hydrochloric acid.

Section-4. TIPS TO AVOID MISTAKES

Q39. What are the main mistakes in maintenance?

1. Cleaning only with water

2. Not replacing the cleaning solution

3. Cleaning mop head is not kept clean

4. Floor is not vacuumed or dusted enough

5. Not using a door mat

6. Using the wrong cleaning chemical

7. Not having a planned program for maintenance

Q40. Are they some tips to avoid mistakes during maintenance?

Here are some useful tips-

Use walk – off mats

To reduce the possibility of unsightly scratches and/or dulling of the marble or limestone floor, install walk off mats inside and outside all entry doorways. Good quality walk-off mats will remove sand and grit from the bottom of a person’s shoe that could otherwise badly scratch and dull the marble floor.

Dust Mop & Sweep Regularly

Walk-off mats will reduce the amount of abrasive soils that can enter from shoes, however, they cannot completely eliminate all materials that can scratch or dull a stone surface. Many abrasive soils are generated inside the house like very small pieces of broken glass or porcelain, metal chips or flakes, or sand and dirt brought in/on clothing or other materials. Dust mopping and sweeping will help remove these abrasive contaminants. Use a clean, untreated and dry dust mop or fine bristle broom and dust pan to remove all dust, dirt and loose debris daily or as needed. This is the most important thing you can do to keep the stone surface looking new.

Utilizing a neutral non – residual water based stone cleaner or a slightly alkali cleaner, damp mop regularly. Spot cleaning can be accomplished by simply applying a small amount of this neutral cleaner to a soiled spot, lightly rubbing to dissolve the spot and remove with a clean damp sponge.

Don’t clean only with water

This can be very detrimental to your soft stone. Water contains chlorine, salts and other minerals that will diminish the shine if used on a regular basis. In addition, water doesn’t have the ability to cut through dirt and mainly dust will be removed. Utilize neutral, non-residual water based stone cleaner, damp mop regularly. Spot cleaning can be accomplished by simply applying a small amount of this neutral cleaner to a soiled spot, lightly rubbing to dissolve the spot and removing with a clean damp sponge.

Replace the cleaning solution frequently

Otherwise, it will leave streaks all over the stone surface and the grout joints (especially if they are light colour) will get dirty very rapidly. Whenever you notice that the cleaning solution becomes cloudy and dirty, immediately replace it with a fresh new solution.

Keep the cleaning mop head always clean

By using mop or cloths that are soiled and dirty, you are actually tracking the dirt back into the floor and grout joints. Dirty mops can create streaks and an unattractive look. Keep the cloth or mop head clean all the time. Wash them thoroughly after you have finished the cleaning with neutral soap and warm water.

Use the right cleaning chemicals

In case you use the wrong cleaning chemical you can ruin your stone floor very easily. Especially soft stones made from calcium carbonate are very sensitive to any acid or high alkaline chemicals. Do not use any tile cleaners, vinegar, ammonia, alcohol etc. Use only neutral cleaners that have pH 7.00 or slightly higher and were made specially for cleaning stone. In this way you prolong the stone life.

Make a planned program for maintenance

Designate the cleaning days and polishing dates and the days that you want to re-apply the protection depending on the abuse and foot traffic. Doing that will keep the floor well maintained.

Section-5. GENERAL INFORMATION

Videos and Presentations will be made available soon.

I-1. Videos

- How to make Anti-slippage floorings- How to apply an oil- and water repellent protection on a kitchen top

- How to apply a color enhancing protection

- How to renew the gloss of a stone floor

- How to remove acidic stains and lime scale

- How to remove organic discolorations

- How to repair small holes and scratches (fine cracks) without having to regrind and re-polish the whole surface

I-2. Power-Point

- How to repair and renew an old floorAcknowledgement: WONASA would like to thank the company AKEMI (www.akemi.de) for the preparation of this Guide

Introduction: IMPORTANCE OF KNOWING THE STONE MATERIALS

Natural stone is one of the most ancient building materials that has accompanied us since our origins. However, strangely, it remains unknown in so many ways to most of us.

To know the materials and understand their technical characteristics has become indispensable for the industry since offering this information to all the interested agents will make its use easier.

The aim of this Guide is to give technical information on natural stone so as to increase the knowledge of it, the specifications and use.

Technical Characteristics Of Stone

When electing a material we need to know its capabilities that will adapt to the project.

One should to take into account that all the stones have possible uses, but not all the stones can be used for all the applications. To give an example: knowing what is the degree of absorption of water of a stone will help us to decide if it is valid or not for use as cladding material in a swimming pool.

How can one know what are the characteristics on which to focus for a stone for a particular use? We will now try to summarise them below.

From Where Do The Norms Come Which Define The Requisites Of A Stone For Construction?

The requirements for a stone will depend on the country where the stone is found or the country of its destination.

We can find requisites related to the material itself (granite, marble, limestone, etc.) with the construction producto (tiles for pavements, slabs for facades, etc.) or the construction system used.

How Does One Know What Tests Need To Be Done To The Materials?

It is important to know that, from one country to another, the requisites needed as also the testing methods may vary by which one arrives at a result.

For example, the ASTM norms indicate some minimum values for the type of stone being examined, however, in the majority of the European countries there is no limit for the materials, but it is regulated as a function of the use that is made of the material.

On the other hand, if one is talking of the testing methods, these can also vary from one country to another. As an example, the method for determining the resistance to slippage of a stone is different if done in Spain (the pendulum method) to that in Germany (method of the ramp), to that in USA (method of slider).

What Is The Obligatory EC Marked In Europe?

The marked EC indicates that the manufacturer of the product has assured that the harmonised norms have been met. Till now the marked EC in natural stone is obligatory for kerbstones, pavers and tiles for exterior and interior pavements, slabs for facades, tiles for cladding of floors and walls and pieces for manufacture of brickwork , i.e., ashlar walls and similar things.

The manufacturers then need to put in place Control Systems of Production, do initial testing on the products and, with certain frequency, new control tests.

The results of the tests obtained are embodied in two documents: a declaration of Capabilities and the marked EC is put on the products.

As a Producer, What Does One Have To Give To The Clients?

If one is selling within the EU, one needs to give a Declaration of Capabilities of ones products. In other countries one needs to follow the norms that can have effect but, in all cases, it is important to understand that it is always necessary to do testing frequently of the stone materials and this must be available in the form of ' technical characteristics' with at least the most important test results.

What Are The Characteristics Currently Considered Most Important?

In any techcnical data of a stone it is recommended there be information on some of the following tests: resistance to flexion, resistence to compression, water absorption, density and porosity.

There are other important tests but that would depend on the application being made of the stone, which could be tests on slippage, or wearing out in a pavement, or tests of resistance to ice in cold climates.

Now to deal with the ideas of the tests that represent the most important characteristics so as to understand their usefulness.

What Is The Significance Of The Results Of The Most Important Characteristics?

Resistance to Flexibility

Let us say that flexibility is the deformation that can take place in any element in the perpendicular direction to its longitude axis. This type of stress is undergone by tiles or slabs on the facades.

The test is done with a press that keeps increasing the load on the material till its breakage.

Knowing the value of resistance to flexibility is fundamental. A number for resistance of a stone by itself does not indicate that the material is 'better or worse' for a particular application, but one needs to adequately calculate the dimensions.

In natural stone, the values of resistance to flexibility can vary very much from one material to another. For example, some limestones or sandstones can give values from 2 to 3 Megapascals (MPa) and, on the other hand, slates can give values that can go up to as much as 60 MPa, or more.

The following table portrays orientative values of resistance to flexibility for different types of stones:

| Resistance To Flexibility (Mpa) | Quartzites | Granites | Marbles | Limestones | Sandstones |

|---|---|---|---|---|---|

| LOW | <6 - 9 | <5 - 8 | <4 - 7 | <3 | <3 |

| MEDIUM | 9 - 20 | 8 - 16 | 7 - 15 | 3 - 6 | 3 - 6 |

| HIGH | >20 | 16 - >20 | 15 - >20 | 6 - >8 | 6 - >8 |

Resistance to Compression

The compression load represents the flattening load, for this the testing is important for stone products that are installed in a big way such as cobblestones or ashlars for walls. The testing is done with a press subjected to loads that flatten it.

As orientation, the following table portrays the values of resistance to compression for different types of stones.

| Resistance To Compression (Mpa) | Quartzites | Granites | Marbles | Limestones | Sandstones |

|---|---|---|---|---|---|

| LOW | <70 | <80 | <50 | <30 | <30 |

| MEDIUM | 70 - 150 | 80 - 150 | 50 - 120 | 30 - 100 | 30 - 80 |

| HIGH | >150 | >150 | >120 | >100 | >80 |

Water Absorption

The capacity of water absorption of a stone is specially important for some applications.

The values of atmospheric water absorption of natural stone can range from almost zero, close to 0% in some marbles and granites, to values of 10% or more for not very dense limestones. The table below shows some common and orientative values:

| Water Absorption (%) | Quartzites | Granites | Marbles | Limestones | Sandstones |

|---|---|---|---|---|---|

| LOW | <1 | <0.3 | <0.1 | <2 | <3 |

| MEDIUM | 1 - 3 | 0.3 - 1 | 0.1 - 0.8 | 2 - 7 | 3 - 10 |

| HIGH | >3 | >1 | >0.8 | >7 | >10 |

There are also products that can seal the pores of the stones. These are chemical and water repellant products aimed at waterproofing.

Density

The density of stone is measured in kgs per cubic metre of material. Greater the density, less is the percentage of porosity and greater the strength and, normally, less capacity of absorption.

Within each variety of rock there can be more or less dense stones, even so one can provide, as an example, the following table of values:

| Density (kg/cm3) | Quartzites | Granites | Marbles | Limestones | Sandstones |

|---|---|---|---|---|---|

| LOW | <2500 | <2500 | <2500 | <1700 | <1900 |

| MEDIUM | 2500 - 2800 | 2500 - 2800 | 2500 - 2800 | 1700 - 2200 | 1900 - 2500 |

| HIGH | >2800 | >2800 | >2800 | >2200 | >2500 |

Porosity

The porosity is closely linked to density: more the pores, less dense is the material, i.e., less weight per unit volume.

The porosity is given in percentage, and can vary a lot from one material to another, from less than 1% till much higher values for very porous stones such as limestones, travertines and similar.

| Open Porosity (%) | Quartzites | Granites | Marbles | Limestones | Sandstones |

|---|---|---|---|---|---|

| LOW | <0.4 | <0.4 | <0.3 | <1 | <1 |

| MEDIUM | 0.4 - 1.3 | 0.4 - 1.3 | 0.3 - 1.3 | 1 - 5 | 1 - 15 |

| HIGH | >1.3 | >1.3 | >1.3 | >5 | >15 |

Resistance to Wearing Out

Wearing out has to do with the traffic over the surface of a tile or pavement.

There are several ways of measuring the wearing out. The American method gives a result in the form of an index ((Iw), other methods provide a result in millimetres.

It is an important characteristic to determine when dealing, for example, with pavements with very high traffic such as shopping centres, train stations, airports, etc.

Resistance to Slippage

It is the capacity of a stone to resist the slippage of a person due to the surface. There are several ways of measuring though the most commonly used is the pendulum of friction, of which one can see the image below:

The great advantage of this method is one can do testing at site, i.e., out of the laboratory. Other methods, such as the German, that of the ramp, or that used in USA, BOT 3000, also result useful to determine this characteristic.

Depending on the country of destination one can observe the requirements. In a general way, in Europe, the values of slippage greater than 35 are considered safe against slipping. If, on the contrary, one measures with the German method, one will determine the type of slipperiness( from R9 to R13). In USA, on the contrary, one measures the coefficient of dynamic friction, with results between 0 and 1.

Name of the Stone

When one talks of the name of the stone one refers to the commercial denomination and its petrographic denomination.

The commercial denomination is the one that is adopted by the manufacturer and supplier. It is common that a stone from the same exploitation be given different names when processed and commercialised by different companies.

The petrographic denomination of a rock is that one which is determined after a petrographic study with the microscope.

To give an example of this, a granite, commercially denominated ROSA PORRIÑO, referring to its characteristic colour, is, petrographically, a biotitic granite. These two names ought to be clearly identified in a data sheet, same as the origin of the material (location of the quarry).

Other characteristics related to the peculiarities of the project:

Each project has its conditions and distinct peculiarities. For example, in external areas where there is risk of frequent snowfall, it is important to to be clear of the resistance of a stone to the cycles of frosting and defrosting. When there is a strong exposure to high temperatures or to important thermal shocks one must determine the changes that take place in the material and, if relevant, the coefficients of thermal expansion of the stone. If the area where the stone is used is close to the sea or to a salty environment, it will also be necessary to judge these aspects.

The table below indicates, as an orientation, the different coefficients of thermal expansion of some natural stones.

| Type of Stone | Coefficient of Thermal Expansion |

|---|---|

| Quartzites | 3 x 10-6 to 7 x 10-6 |

| Granites | 5 x 10-6 to 9 x 10-6 |

| Marbles | 3 x 10-6 to 6 x 10-6 |

| Limestones | 3 x 10-6 to 7 x 10-6 |

| Sandstones | 2 x 10-6 to 7 x 10-6 |

What Are The Requirements In a Stone For Pavements?

If one is going to choose a stone for pavements one should take into account the following characteristics:

Resistance to flexibility

Currently whenever big size and slender formats are installed it becomes especially relevant to calculate the adequate thickness of the tile.

That a stone has a higher resistance to flexibility, or lower, does not mean it is a worse material but that, under the same conditions, the one with greater thickness will be installed.

When dealing with cobblestones the resistance to compression will be the most important characteristic.

Absorption of water and porosity

Depending on the degree of humidity in the environment one may need to limit the requisites, it is more important if one is talking of exterior pavings or whether it is in frequent contact with water.

The American norms ASTM establish recommendations for water absorption at atmospheric pressure depending on the type of stone, for example 0.4% for granite and 0.2% for marble.Resistance to sliding

Limiting the possible slippage of the pavement users is extremely important to guarantee the safety in usage, above all in exterior or interior pavements where there is a risk of liquids spilling over. One needs to fulfil the requisites established in the destination country.

Resistance to wearing

The wearing out that is produced over time due to passage on the pavement surface is not a trivial matter. In some countries limits to resistance to wearing is recommended as a function of usage of the pavement with more or less intensity of traffic.

For Facades What Requisites Should a Stone Have?

When it comes to facades one needs to take into account, generally speaking, the following characteristics:

Resistance to flexibility

For the same reason as in the case of pavements one needs to know the resistance to flexibility to give an adequate dimension to the pieces which will comprise the facade.

Water absorption

In soles of the facades (lower parts) which are in constant contact with water (of the side walks and terraces) one needs to control the water absorption due to capillarity.

Resistance to anchors

It is convenient that for any stone that is going to be installed with anchors in the edges or in the back side testing be done to know the resistance to these types of anchors.

Counter Tops

The countertop is usually a star product of the aesthetically spectacular stones. It is important that the stones that are destined for countertops have:

- With very little or no porosity, close to 0 %, therefore occasionally products are applied to improve this characteristic.

- They are not easily stained: there is a test for this that determines the sensibility to accidental staining of the stone, which can be done with distinct agents of stains in a particular moment, for example, coffee, oils, wine, etc.

- That the thermal shocks do not affect them. Those produced by supporting a very hot plate on its surface.

- That it be resistant to scratching of the possible sharp tools used in the kitchen.

Acknowledgement: WONASA would like to thank Ms. Eva Portas Fernández for the preparation of this Guide

Comparative Stone Quarrying policies in different countries

Q1. What is the period of lease that is awarded for stone mining in your country?

BRAZIL

There is no leasing period. Once the miner is commissioned with a Mining Authorization, he can hold the lease as long as its proved reserves allow him. He initially files at ANN a Mining Plan, with a feasibility study indicating the expected monthly production. If we divide the overall approved reserves by the monthly production we will have the mine lifetime. If the miner does not re-evaluate reserves within this period, his lease will end with the exhaustion of the reserves. Sub-lease is allowed for a maximum period of 30 years.

EGYPT

15 years.

FINLAND

In Finland, quarrying of granite and schist is ruled by the Land Extraction Act, and a land extraction permit and an environmental licence is acquired, while the extraction of soapstone and marble is covered by the Mining Act, and a mining permit and an environmental licence is required. The land extraction permit that is awarded for stone quarrying in Finland is 10, 15 or 20 years.

INDIA

20 years + 20 years.

PORTUGAL

Currently there is no limit. According to the new legislation (not yet published) the duration is 50 years.

RUSSIA

5-49 years.

SPAIN

Depends on the qualification of the resource, which means that small quarries that produce construction materials are authorized until the resource is finished in that area of exploitation or the period estimated in the Project that all that present rock is going to be extracted. After that period can be renewed. In block quarries are granted for 30 years renewable up to 90 years or 75 depending on the area where the quarry is located.

SWEDEN

Between 25-40 years will be granted as concession by the authorities. Contract with landowner signed on same term.

TURKEY

Period of the license is 20 years when first awarded.

Q2. When it comes to renewal of the lease, what is the prevailing policy?

BRAZIL

Since the lease is not subject to renewal, there is no valid policy for that. However, miner cannot stop production without government authorization, needs to file yearly production reports, pay government royalties and follow the environmental plan approved. If he fails to meet these criteria he might get his mining claim canceled.

EGYPT

Renewal is on annual basis. For a 15 years period approval is needed from the Parliament.

FINLAND

Case by case, but usually no problem to get renewal.

INDIA

One needs to apply for renewal, and the process is not very complicated.

PORTUGAL